This project was to create a CNC milling machine that was capable of cutting foam in order to create a buck for a mould for a car.

The initial design was to allow a whole car to be milled from a single block of foam, but this was deemed too large, so it was reduced to a third of the length of the car - which was still big.

Its total millable volume was 2x2x1.5m

This project had a very similar design goal to the first - however, smaller blocks would be milled, and they would be glued together to form the buck.

Its total millable volume was 1.5x1.5x0.15m

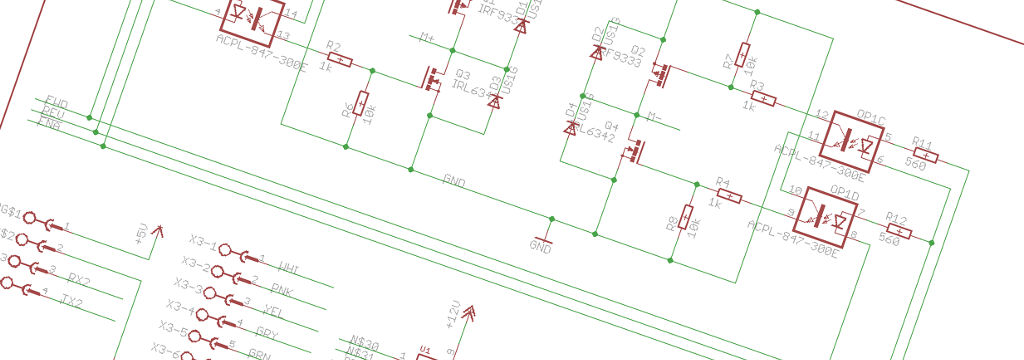

It was eventually adapted to make a CNC plasma cutter, to be used to cut steel into precise shapes.

Our client was finding it difficult to source parts for their agricultural machine, and also wanted to make life easier for their operators.

So we were asked to come up with a solution to both requirements - and the automatic gear change project was started.

At the time of writing, this is still in progress, having gone through the initial prototype phase, and now going through a second prototype.