The overall design brief for this project is as follows:

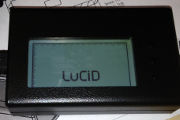

Originally, the LuCiD was going to use a 3-character 7-segment LED, and would only display the IP address of the hardware. However, this was deemed too limiting, so a 16x2 character LCD was used instead.

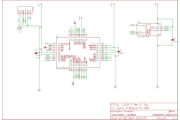

A mini-USB connector attached it to the hardware, and a Microchip PIC drove the LCD, with signals given from a service running on the hardware that would display programmable information.

Two buttons allowed user interaction - such as rebooting the hardware, or restarting other services.

With an initial prototype completed, ways to improve it were investigated.

A 128x64 LCD monochrome graphical display that allowed the hardware to display charts of its current status was found which was not much more expensive than the monochrome display. A third button improved the UI capabilities.

A prototype box was manufactured (this was before we had a 3D printer), which allowed the client to have a feel as to what the real product would be like.

By searching outside of the UK, we were able to source a colour 128x64 LCD - with a touch screen. And it was cheaper than the displays in the earlier versions.

This meant there was no need for any buttons whatsoever - the engineer would only need to touch the screen, and various menu options would be available to them.

An additional design goal was to allow it to be incorporated into the client's hardware at a later stage - which meant the design had to be shrunk.

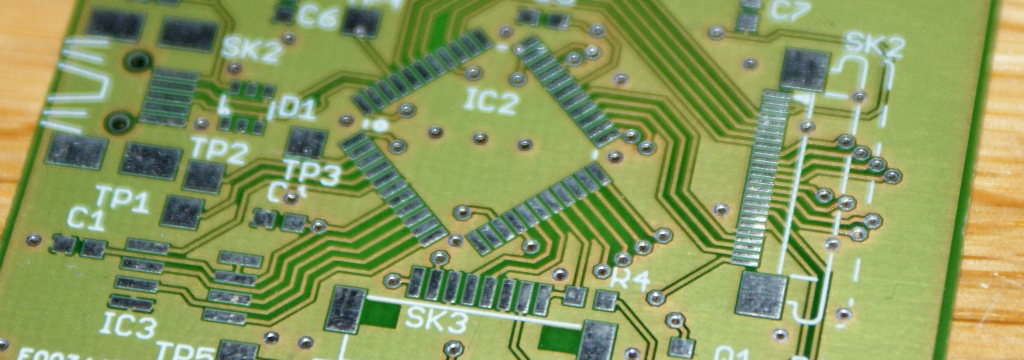

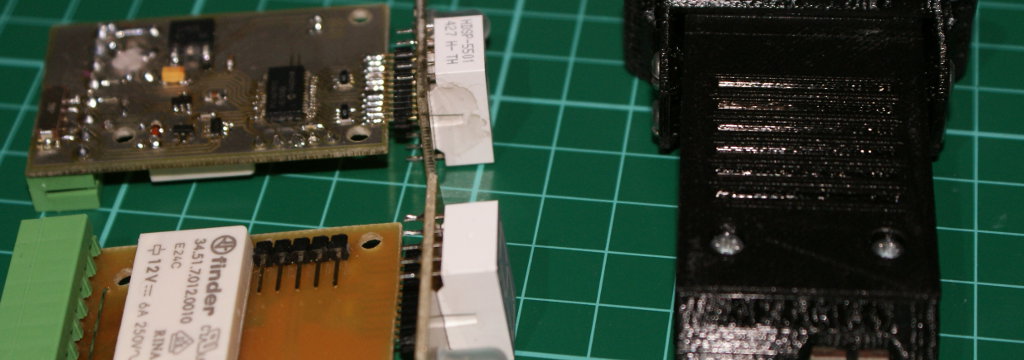

In order to accomodate this, an initial functional prototype was made, and then prototype circuit boards were manufactured using our third-party manufacturer.

A 3D printed case finished off the final prototype design, which was attached to a lanyard, so it could be easily transported around the engineer's neck - or possibly a key-ring (although it is a little large for that).